Model NO.: XLB-350

Condition: New

Color: Customized per Customer Requirements

Motor Power: 2.2kW

Working Layers: 1, 2, 4 (Customizable)

Outline Dimension: 570 x 1450 x 350 mm

Delivery Time: Within 30 Working Days After Deposit Received

Payment Terms: T/T or L/C

Trademark: BOJIA

Transport Package: Standard Export Packing

Specification: Weight: Approximately 1000 kg

Origin: Qingdao, China

HS Code: 8477800000

PLC Controlled Laboratory Plate Vulcanizing Machine

I. Key Features of the Machine

1. Four Column Structure for Stability

2. 3RT (Three Stage Die Sinking) for Precision

3. PLC Programmable Controller for Advanced Control

4. Self-Diagnosis and Display Function for Easy Troubleshooting

5. Pressure Transducer Control System for Accurate Pressure Monitoring

6. Tubular Electric Heating Elements with Fuse Alarm for Safety

7. Easy Maintenance and Replacement of Heating Elements

II. Technical Specifications

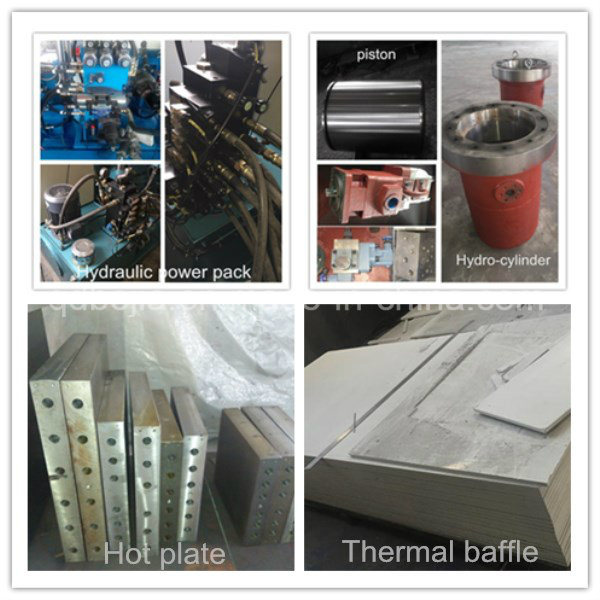

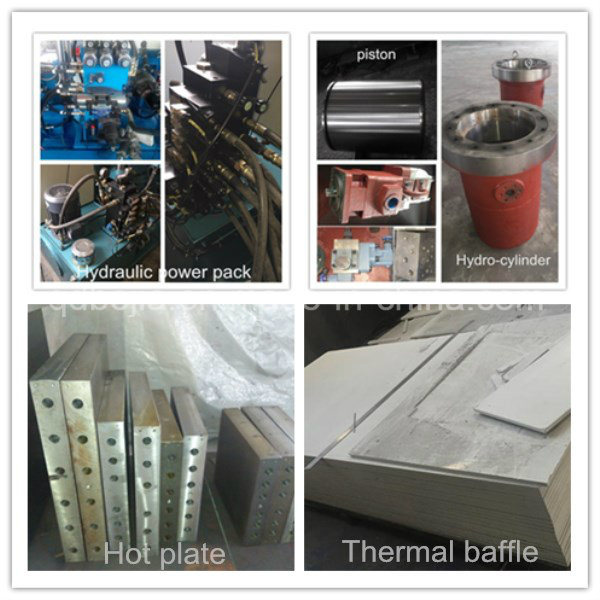

III. Product Images

IV. Our Products

Our company specializes in manufacturing a wide range of rubber processing equipment, including laboratory plate vulcanizing machines, frame-type vulcanizing presses, four-column vulcanizing presses, rubber mixing mills, batch coolers, extruders, rubber strip making machines, and tire recycling equipment.

V. Our Services

1. Pre-shipment Testing: All machines are tested for 3–5 hours under full load before delivery. We will provide video footage for your review, allowing you to start using the machine immediately and saving time and costs on testing. You're also welcome to visit our factory for inspection and testing.

2. Warranty: We offer a 12-month warranty after installation. If any issues arise, we will respond promptly and provide the best possible support to ensure your satisfaction.

I. Key Features of the Machine

1. Four Column Structure for Stability

2. 3RT (Three Stage Die Sinking) for Precision

3. PLC Programmable Controller for Advanced Control

4. Self-Diagnosis and Display Function for Easy Troubleshooting

5. Pressure Transducer Control System for Accurate Pressure Monitoring

6. Tubular Electric Heating Elements with Fuse Alarm for Safety

7. Easy Maintenance and Replacement of Heating Elements

II. Technical Specifications

| Model | 25T |

| Nominal Clamping Force (KN) | 250 |

| Max Oil Pressure | 16 MPa |

| Hot Plate Size (mm) | 350 x 350 |

| Hot Plate Space (mm) | 125 |

| Working Layers | 2 |

| Plunger Stroke (mm) | 250 |

| Heating Mode | Steam or Electric Heating |

| Hot Plate Pressure per Unit Area | 2.04 MPa |

| Motor Power (KW) | 2.2 |

| Overall Dimensions (mm) | 570 x 1450 x 350 |

| Weight (KG) | 1000 |

III. Product Images

IV. Our Products

Our company specializes in manufacturing a wide range of rubber processing equipment, including laboratory plate vulcanizing machines, frame-type vulcanizing presses, four-column vulcanizing presses, rubber mixing mills, batch coolers, extruders, rubber strip making machines, and tire recycling equipment.

V. Our Services

1. Pre-shipment Testing: All machines are tested for 3–5 hours under full load before delivery. We will provide video footage for your review, allowing you to start using the machine immediately and saving time and costs on testing. You're also welcome to visit our factory for inspection and testing.

2. Warranty: We offer a 12-month warranty after installation. If any issues arise, we will respond promptly and provide the best possible support to ensure your satisfaction.

Pipe Injection Molding Machine

-

Precision Manufacturing:

- The machine is capable of injecting molten PVC into molds with extreme accuracy, ensuring consistent wall thickness and dimensions for the water pipes.

- The molds are designed specifically for PVC pipes, providing optimal cooling and hardening processes to produce pipes with high durability.

-

High Efficiency:

- The injection molding process is automated, minimizing manual labor and reducing production time.

- The machine can handle multiple molding cycles simultaneously, allowing for faster output of PVC water pipes.

-

Versatility:

- The PVC Water Pipe Injection Molding Machine can be configured to produce pipes of different diameters, thicknesses, and lengths.

- It can also accommodate different types of PVC materials, depending on the application requirements.

-

Energy Efficiency:

- The machine is designed to minimize energy consumption during the injection molding process, reducing operating costs.

- It also features energy-saving modes that can be activated during periods of low production.

-

Ease of Maintenance:

- The machine is built with easy access to critical components, allowing for quick and simple maintenance and repairs.

- It also comes with detailed maintenance manuals and support from manufacturers, ensuring continued optimal performance.

Advantages:

-

Cost-Effectiveness:

- The PVC Water Pipe Injection Molding Machine provides a cost-effective way to produce large quantities of PVC water pipes.

- It reduces material waste and rejects due to its precision and repeatability.

-

High-Quality Products:

- The pipes produced by this machine exhibit superior strength, durability, and chemical resistance, making them suitable for a wide range of applications.

-

Scalability:

- The machine can be scaled up or down depending on production demands, allowing manufacturers to flexibly meet changing market requirements.

-

Environmental Friendliness:

- PVC is a recyclable material, and the injection molding process produces less waste compared to traditional manufacturing methods.

Large Tray Making Machine,Injection Molding Machine Of Pipes,PVC Special Injection Moulding Machine ,desktop plastic injection machine

Ningbo Outai Plastic Machinery Technology Co.,Ltd , https://www.outacmachine.com