Choosing the Right Robotic Welding Process and Equipment for Your Application

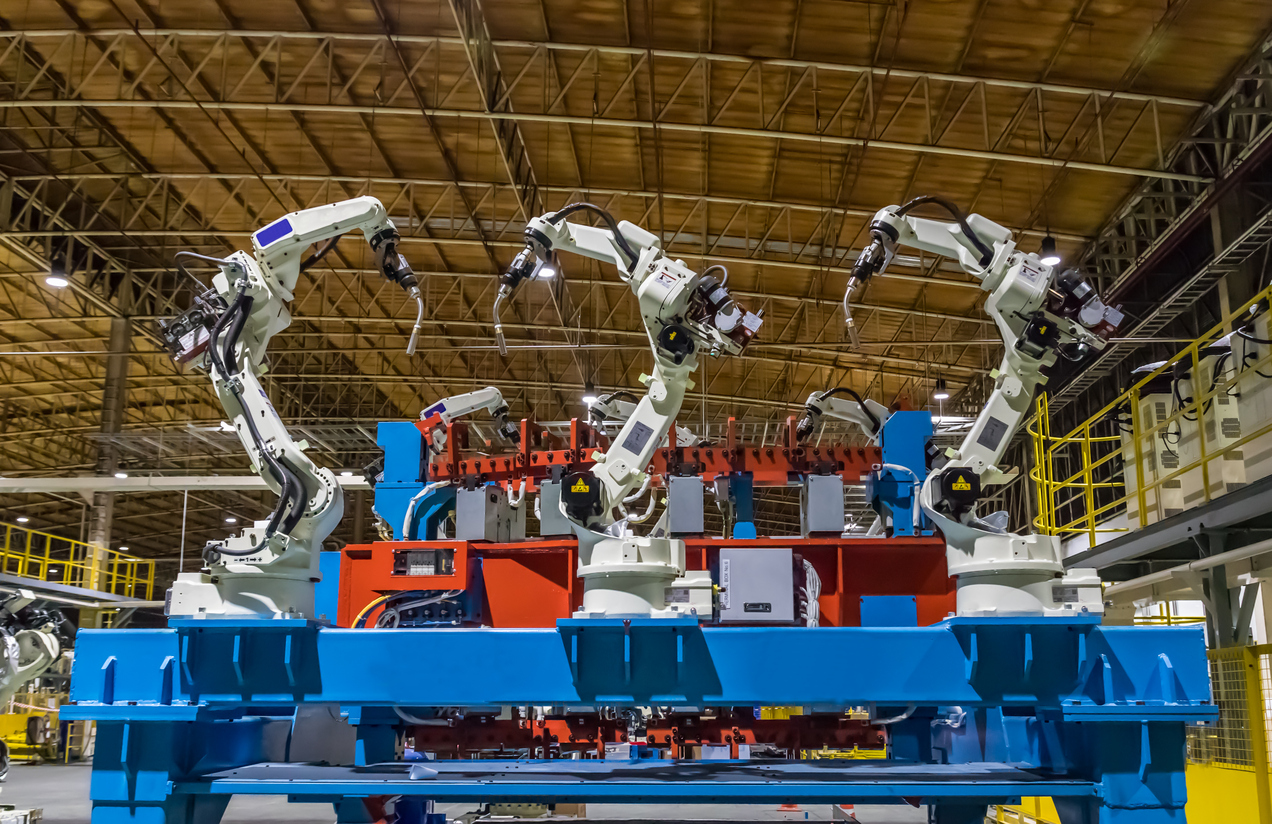

Robotic welding has revolutionized the manufacturing industry by offering increased efficiency, precision, and consistency compared to traditional manual methods. With higher productivity, better quality control, and reduced labor costs, robotic welding systems are now a common choice across various industries. As technology continues to evolve, selecting the right process and equipment becomes more critical than ever.

If you're new to robotic welding, choosing the appropriate system can be overwhelming due to the wide variety of options available. Understanding your specific application needs is essential in determining which robotic welding solution will deliver the best results. Let’s explore the key factors that should guide your decision-making process.

Common Types of Robotic Welding Processes

There are several welding processes suitable for robotic applications, each with unique benefits and ideal use cases. The most commonly used include:

- Resistance Spot Welding (RSW): Ideal for joining thin metal sheets, often used in automotive manufacturing.

- Laser Welding: Offers high precision and speed, perfect for delicate or complex parts.

- Gas Metal Arc Welding (GMAW): Also known as MIG welding, it's versatile and widely used for thicker materials.

- Gas Tungsten Arc Welding (GTAW): Known as TIG welding, it provides excellent control and is ideal for high-quality welds.

- Plasma Arc Welding: Offers deep penetration and is used in specialized industrial applications.

- Laser Hybrid Welding: Combines laser and arc welding for improved efficiency and strength.

Each process has its own set of advantages and limitations, so it's important to match the process to the material, thickness, and required joint quality.

Key Considerations for Robotic Welding Equipment

In addition to the welding process, the choice of equipment plays a crucial role in the success of your robotic welding setup. This includes not only the robot itself but also the peripherals and consumables that support the welding operation.

Automation peripherals such as wire feeders, torches, and cleaning stations help maintain consistent performance and reduce downtime. Consumables like nozzles, contact tips, and liners must be selected based on the type of welding and the frequency of use. High-quality components can significantly improve the longevity and reliability of your system.

Moreover, integrating advanced software solutions—such as real-time monitoring, predictive maintenance, and data analytics—can enhance productivity and provide valuable insights into your welding operations. These tools help optimize performance, reduce errors, and ensure smoother production flow.

Investing in a well-rounded robotic welding system, including the latest hardware and software, can give your business a competitive edge in today’s fast-paced manufacturing environment. It's not just about the robot—it's about the entire ecosystem that supports it.

By carefully evaluating your requirements and understanding the capabilities of different welding processes and equipment, you can make an informed decision that maximizes efficiency and ROI. Whether you're looking to automate a small-scale operation or scale up for mass production, choosing the right robotic welding solution is essential for long-term success.

To learn more about how to integrate robotic welding into your workflow, explore our comprehensive services at Genesis Systems Group.

Posted in Robotic Weldingservice valve, Air conditioner service valve, three-way valves, Refrigeration equipment service valve

SUZHOU YOUDE ELECTRIC CO., LTD. , https://www.unitekool.com