What is NDT (Non-Destructive Testing)?

Non-Destructive Testing, or NDT, refers to a range of inspection techniques that allow professionals to assess the condition of materials, components, or systems without causing any damage. These methods are essential in ensuring the safety and integrity of critical infrastructure across various industries.

NDT stands for Non-Destructive Testing. It's a process used to evaluate the properties of a material, system, or component without altering it permanently. This technique is widely used in industrial, medical, and other fields where the integrity of the object being tested is crucial.

In many contexts, NDT serves as an umbrella term covering all non-destructive inspection approaches, tools, or even the entire field of non-destructive testing. From checking the strength of a bridge to examining the internal structure of a human body, NDT plays a vital role in maintaining safety and quality standards.

Commercially, the main goal of NDT is to ensure that critical structures, like pipelines or power plants, are maintained properly to prevent catastrophic failures. While NDT is often associated with industrial applications, such as inspecting pressure vessels in oil refineries, its use in medicine is also widespread.

For example, an ultrasound scan during pregnancy or an X-ray to check for fractures are classic examples of NDT in action. Even simple visual inspections by the naked eye can be considered NDT if they are done without damaging the object being examined.

It's important to note that NDT doesn't always require advanced equipment. Sometimes, a trained inspector can detect issues just by looking closely at a surface or listening for unusual sounds. However, when more detailed analysis is needed, specialized tools like ultrasonic sensors or radiography devices come into play.

The key principle behind NDT is the ability to gather valuable information without compromising the integrity of the material being tested. This makes it a preferred method in many scenarios where destructive testing would not be practical or cost-effective.

What Is NDT?

We've already covered what NDT stands for and how it's used in different fields. Now let's dive deeper into the details that define the world of NDT.

The Importance of NDT

Ensuring that assets are well-maintained is crucial for operational efficiency and safety. The importance of NDT cannot be overstated, as it offers several advantages over traditional destructive testing methods.

Here are some of the top reasons why companies around the world rely on NDT:

-

Savings. NDT allows for the evaluation of materials without destroying them, which saves costs and resources. This is especially beneficial in industries where replacement parts are expensive or hard to find.

-

Safety. Most NDT techniques are safe for personnel, making them ideal for environments where health and safety are top priorities.

-

Efficiency. NDT methods enable quick and thorough evaluations of assets, which is essential for maintaining continuous operations in high-risk areas.

-

Accuracy. NDT procedures are known for their precision, providing reliable data that supports informed decision-making and long-term maintenance planning.

"NDT is the backbone of a well-managed facility, and its significance is recognized by every trained inspector. The accuracy and repeatability of NDT results depend heavily on the expertise of the technicians performing the tests. They must not only be certified in specific NDT methods but also have a deep understanding of the equipment used to collect data. Knowing the capabilities and limitations of the tools is crucial for making accurate assessments."

- Jason Acerbi, General Manager at MFE Inspection Solutions, "Your One Stop Inspection Source"

Where is NDT Used?Â

Depending on how broadly you define NDT, it could be said that it's used in almost every industry, since visual inspections—whether formalized or informal—are part of daily operations in many workplaces.

That being said, certain industries have formalized processes for using NDT, often guided by standards set by organizations like API and ASME. These industries include:

-

Oil & Gas

-

Power Generation

-

Chemicals

-

Mining

-

Aerospace

-

Automotive

-

Maritime

In these sectors, inspectors often need to access difficult or elevated locations. Common methods include:

-

Scaffolding. Inspectors work at height using scaffolding to collect data directly from the asset.

-

Rope Access. Inspectors use ropes to reach high places safely and efficiently.

-

Drones. Drones allow for remote data collection, keeping inspectors out of dangerous or confined spaces.

NDT Codes and Standards

NDT techniques are used for a wide variety of inspections. However, certain types of NDT, such as those applied to boilers and pressure vessels, are particularly important due to the potential risks involved.

Because of this, most countries have regulations requiring companies to follow strict inspection codes and standards. These guidelines typically specify how often inspections should be conducted and who should perform them. In high-risk situations, inspections must be carried out by certified professionals and approved by authorized witnesses.

Some of the most widely recognized organizations that create NDT standards include:

-

API (American Petroleum Institute)

-

ASME (American Society for Mechanical Engineers)

-

ASTM (American Society for Testing and Materials)

-

ASNT (American Society For Nondestructive Testing)

-

COFREND (French Committee for Non-destructive Testing Studies)

-

CSA Group (Canadian Standards Association)

-

CGSB (Canadian General Standards Board)

What Is the Difference Between Destructive Testing and Non-Destructive Testing?

Non-Destructive Testing (NDT) involves collecting information about a material without altering it, while Destructive Testing (DT) requires changing or damaging the material to obtain data. The key difference between the two is whether the material remains intact after testing.

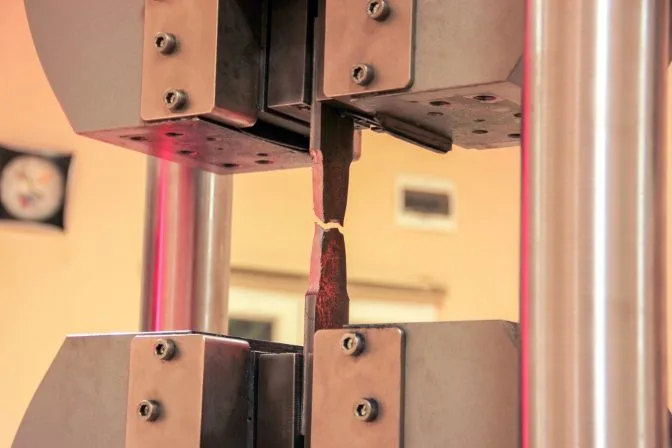

In Destructive Testing, for instance, a sample might be cut, heated, or otherwise altered to analyze its properties. This approach is useful when the goal is to understand the material's behavior under stress or failure conditions.

Examples of destructive testing include:

-

Macro sectioning. A small portion of a welded material is polished and etched for examination.

-

Tensile testing. A sample is stretched to determine its strength and failure point.

-

3 point bend testing. A coupon is bent to test its flexibility and structural soundness.

Read our guide on destructive testing to learn more.

NDT and NDE

While we're defining terms, it's worth noting that there are several phrases commonly used to describe testing without damaging the material. NDT is the most widely recognized, but others include:

-

NDE (Non-Destructive Examination or Non-Destructive Evaluation)

-

NDI (Non-Destructive Inspection)

These terms are often used interchangeably, though they may carry slight nuances depending on context and industry standards.

The 8 Most Common NDT MethodsÂ

There are several techniques used in NDT and NDE to collect various types of data. Each method has its own requirements for tools, training, and preparation. Some techniques provide full volumetric inspection, while others are limited to surface-level assessments.

Here are the eight most commonly used NDT techniques:

-

Visual Testing (VT)

-

Ultrasonic Testing (UT)

-

Radiography Testing (RT)

-

Eddy Current Testing (ET)

-

Magnetic Particle Testing (MT)

-

Acoustic Emission Testing (AE)

-

Dye Penetrant Testing (PT)

-

Leak Testing (LT)

1. Visual Testing (VT)

Definition: Visual Non-Destructive Testing involves examining a material visually to identify any visible signs of damage or wear. This is the simplest form of NDT and can be performed with the naked eye or with the help of tools like inspection cameras.

How to Conduct Visual Testing

Visual Testing can be done with the naked eye, by inspectors visually reviewing a material or asset. For indoor inspections, flashlights are often used to add depth to the object being examined. Remote Visual Inspection (RVI) tools, like inspection cameras, are also used to capture detailed images of hard-to-reach areas.

Read our guide on visual testing.

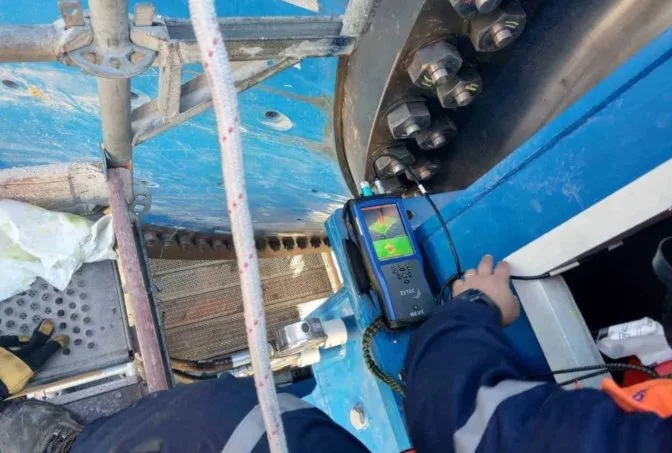

2. Ultrasonic Testing (UT)

Definition: Ultrasonic Non-Destructive Testing uses high-frequency sound waves to detect changes in a material’s properties. This technique is highly effective for identifying internal defects that are not visible to the naked eye.

How to Conduct Ultrasonic Testing

Ultrasonic Testing works by sending sound waves through a material and analyzing the reflections that return. This technique is widely used for detecting cracks, voids, and other internal flaws in materials like metals and composites.

Other types of Ultrasonic Testing include Phased Array Ultrasonic Testing (PAUT), Automated Ultrasonic Testing (AUT), and Time-Of-Flight Diffraction (TOFD).

Read our guide on ultrasonic testing.

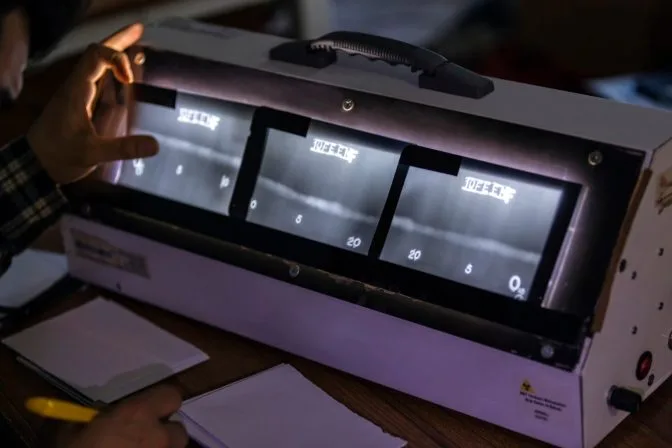

3. Radiography Testing (RT)

Definition: Radiography Non-Destructive Testing uses gamma or X-radiation to examine the internal structure of a material. This method is particularly useful for detecting hidden flaws that are not visible on the surface.

How to Conduct Radiography NDT Testing

Radiography Testing involves directing radiation through the material being tested onto a film or detector. The resulting image reveals the internal structure of the material, allowing inspectors to identify potential issues such as density variations or internal voids.

Read our guide on industrial radiography.

4. Eddy Current (Electromagnetic) Testing (ET)

Definition: Eddy Current Non-Destructive Testing is a method that uses electromagnetic induction to detect surface and near-surface flaws in conductive materials. It is particularly effective for identifying cracks, corrosion, and material thinning.

How to Conduct Eddy Current Testing

Eddy Current Testing involves generating a magnetic field around a conductive material and measuring the resulting eddy currents. Any disruptions in the current flow indicate the presence of defects or imperfections in the material.

Read our guide on eddy current testing.

5. Magnetic Particle Inspection (MPI)

Definition: Magnetic Particle Non-Destructive Testing is a technique used to detect surface and near-surface flaws in ferromagnetic materials. It relies on the disruption of a magnetic field caused by defects in the material.

How to Conduct Magnetic Particle Inspection

To perform Magnetic Particle Inspection, a magnetic field is induced in a ferromagnetic material. Iron particles are then applied to the surface, revealing any disruptions in the magnetic field caused by defects. These disruptions appear as visible indications of the flaw.

Read our guide on magnetic particle inspection.

6. Acoustic Emission Testing (AE)Â

Definition: Acoustic Emission Non-Destructive Testing is a method that detects acoustic emissions generated by defects within a material. These emissions occur when a material undergoes stress or deformation.

How to Conduct Acoustic Emission Testing

Inspectors conducting Acoustic Emission Tests listen for bursts of acoustic energy produced by defects in the material. By analyzing the intensity, location, and timing of these emissions, inspectors can identify potential issues within the material.

Read our guide on acoustic emission testing.

7. Dye Penetrant Testing (PT)

Definition: Dye Penetrant Testing (also known as Liquid Penetrant Testing) involves applying a liquid penetrant to the surface of a material to detect surface-breaking flaws. The penetrant seeps into cracks and other defects, making them visible under appropriate lighting conditions.

How to Conduct Penetrant Testing

Inspectors apply a penetrant solution to the surface of the material being tested. After removing excess penetrant, a developer is used to draw the remaining solution out of the defects. Fluorescent dyes are viewed under ultraviolet light, while regular dyes are seen against a contrasting background.

Read our guide on dye penetrant testing.

8. Leak Testing (LT)

Definition: Leak Non-Destructive Testing is a method used to detect leaks in vessels or structures. This technique helps identify defects that could lead to performance issues or safety hazards.

How to Conduct Leak Testing

Leak testing can be performed using pressure gauges, soap-bubble tests, or electronic listening devices. These methods allow inspectors to detect leaks without damaging the vessel or structure being tested.

Read our guide on leak testing.

Welding NDT

Welding NDT is the application of non-destructive testing techniques to inspect welds. Welds are one of the most common components that require inspection in industrial settings. Using NDT methods, inspectors can determine whether a weld is strong or has potential defects that could compromise its integrity.

The most common flaws found in welding NDT include:

-

Poor weld quality due to the presence of slag

-

Fatigue caused by human error

-

Flaws caused by incorrect technique or setup during welding

-

Environmental damage to the weld, such as temperature extremes, moisture, or incompatible materials

Common welding NDT methods include:

-

Ultrasonic Testing (UT)

-

Magnetic Particle Inspection (MT)

-

Acoustic Emission Testing (AE)

-

Dye Penetrant Testing (PT)

-

Radiography Testing (RT)

-

Eddy Current Testing (ET)

A visual inspection can also be used for welding NDT to make basic assessments of weld strength, although its findings may be less detailed than other methods.

Welding NDT test of a crack performed via magnetic particle inspection

Welding NDT test of a crack performed via magnetic particle inspection

The primary objective of using NDT for welding is to identify surface or internal defects that could lead to failure or deterioration of the weld. If a weld fails, the consequences can be severe, especially in critical infrastructure such as boilers or pressure vessels.

What is the best NDT welding inspection method?

While all the above methods can be used for welding NDT, the most effective is ultrasonic testing using the phased array approach. This method is fast, efficient, and provides high-quality data without requiring extensive setup or additional equipment.

Destructive and Non-Destructive Testing in Welding

We've already discussed the primary welding NDT methods, which are used to inspect welds without causing damage. However, destructive testing is also used in some cases to gain a deeper understanding of a weld's internal structure.

The most common types of destructive weld testing include:

-

Guided Bend Weld Test. Bending a sample of the weld to a predetermined radius to assess its internal structure.

-

Macro Etch Weld Testing. Removing a small sample from the weld, polishing it, and etching it with acid to examine its internal composition.

-

Transverse Tension Test. Evaluating the tensile properties of the base metal, weld metal, and the bond between them.

How Drones Can Help with NDT

In recent years, drones equipped with cameras have become a popular tool in NDT for collecting visual data. Initially, drones were limited to providing supplementary visual data, but advancements in technology have allowed them to replace manual inspections in many cases.

Drones are now widely used for Remote Visual Inspection (RVI), enabling inspectors to collect visual data without entering dangerous or hard-to-reach areas. This not only improves safety but also increases efficiency and reduces downtime.

Here are two of the main benefits of using drones in NDT:

Safety

Drones significantly enhance workplace safety by eliminating the need for inspectors to enter hazardous environments. For example, when inspecting power lines or towers, drones reduce the time inspectors spend in the air, minimizing exposure to risks.

Indoors, drones like the Elios 3 can be used to inspect pressure vessels or boilers without requiring inspectors to enter confined spaces. This reduces the risk of accidents and ensures a safer working environment.

Savings

Drones can improve return on investment (ROI) in both indoor and outdoor scenarios, but the savings are particularly significant for indoor inspections. Instead of building and dismantling scaffolding, companies can use professional indoor drones to collect visual data quickly and efficiently.

This reduces downtime and can save up to one or two days per inspection. Additionally, frequent drone inspections can identify issues early, extending the life of the asset and potentially saving hundreds of thousands of dollars in repairs or replacements.

What’s Next for Drones in NDT?

Currently, the primary use of drones in NDT is for visual data collection. However, recent advancements have allowed drones to be equipped with a variety of sensors, including thermal, ultrasonic, magnetic, and radiographic sensors.

New sensor technologies are constantly being developed for use with drones, enabling inspectors to gather a wider range of data without physically touching the asset. This opens up new possibilities for remote and real-time inspections.

Additionally, software designed for NDT is becoming increasingly sophisticated. Tools like Inspector 4.0, the latest version of Flyability’s inspection software, allow inspectors to quickly create 3D models of inspected assets. These models show exactly where defects are located, improving efficiency and accuracy.

Manually reviewing large volumes of data from drone inspections can be overwhelming. As a result, software that helps interpret this data has become essential. Advanced programs powered by machine learning and AI can automatically detect and flag potential issues for further review.

Companies like WinCan are developing AI-powered software specifically for sewer inspections, where the software can analyze raw visual data and identify defects that require attention. These innovations are transforming the NDT landscape, making inspections faster, safer, and more accurate.

Advances in drone technology, payload diversity, and data processing are creating a new era of efficiency and safety for NDT. Read about the seven major benefits drones provide for NDT.

Â

Car Humidifier Essential Oil Diffuser,Car Aromatherapy Diffuser,Car Aromatherapy Essential Oil Diffuser,Car Scented Hanging Diffuser

Guangzhou Chiyang Scent Technology Co., Ltd. , https://www.diffuserscent.com